Volumetric Survey of Tarong PowerStation Ash Storage Facility

Overview

Understanding and managing risk is crucial within the power generation and mineral extraction industries. Risk mitigation underpins safe practice forming a key part planning for production, operations, waste management and rehabilitation. Stringent legislation also requires high standards to be enforced by the industry.

Situation

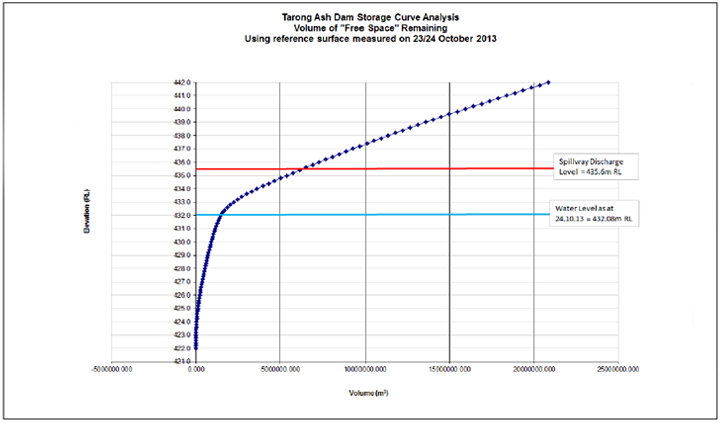

Stanwell Corporation have on-going requirements to assess Tarong’s Ash Storage Facility’s capacity. This is to:

- Monitor the dam’s storage capacity with respect to Design Storage Capacity

- Report updated water quantities to authorities ahead of each wet season

- Assist with planning new rehabilitation strategies.

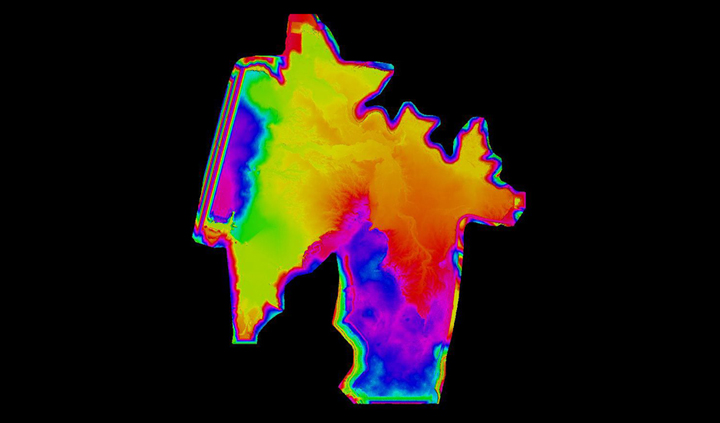

The Ash Storage Facility is made up of an “exposed” ash layer with a major water body between the ash bank and the dam wall. Both the facility’s exposed and submerged must be surveyed to calculate its remaining capacity requiring a combination of complex surveying techniques..

Action

Woolpert employed a combination of bathymetric and airborne LiDAR survey strategies, completing it using an unmanned shallow-water vessel. This system’s benefits includes:

- Eliminating safety concerns by utilising watercraft.

- Collecting accurate data from areas proving otherwise impossible to access.

- Faster mobilisation capabilities for quicker data acquisition

We merged the bathymetric survey data with the airborne LiDAR findings creating a seamless surface of the exposed and submerged areas. Volumetric calculations and storage curves were derived determining current ash and water volumes.

Result

Operations were conducted more safely by eliminating high-risk data collection methods. Our strategy produced a superior overview of the entire facility providing a complete picture of the ash surface. Volumes were also more accurately calculated.

To find out more – email asiapacific@woolpert.com